Blackhawk Ultimate Adjustable Upper Control Arms Released

Many 4x4 owners across Australia have invested significantly in their heavy duty work and off-road leisure vehicles, so it makes perfect sense to fit the highest quality suspension components when upgrading or enhancing the off-road capabilities of these vehicles.

Increasing 4x4 vehicle height has the direct effect of altering the vehicle’s wheel alignment. This in turn leads to premature tyre wear along with less responsive vehicle handling.

Blackhawk 4x4 Ultimate Adjustable Upper Control Arms have been designed to provide a variety of wheel alignment options that were previously unavailable with this level of finesse in 4x4 vehicle specific suspension components.

This new range of on-vehicle adjustable upper control arms allows easy adjustment, thereby alleviating handling issues by returning the suspension geometry and alignment back to factory specification or better. This also complements the travel available from many aftermarket suspension upgrades.

Blackhawk 4×4 Ultimate Adjustable Upper Control Arms include all of the practical features that can be found with 4x4 competition vehicles, refined to best suit harsh Australian off-road conditions. These suspension components also provide the durability and driveability to be expected from a premium quality manufactured product that meets and exceeds Original Equipment specifications.

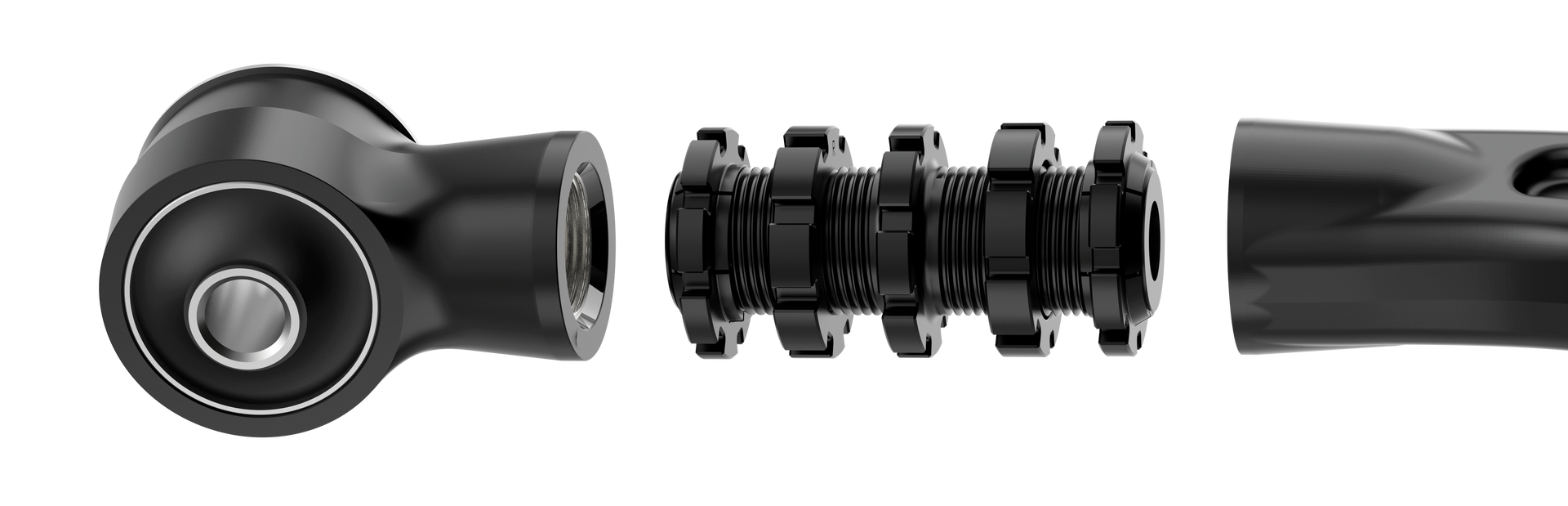

Offering unrivalled innovation, each Blackhawk 4x4 Ultimate Adjustable Upper Control Arm includes a proprietary ball joint that provides a high degree of articulation, enabling more suspension travel. The unique Blackhawk Ultimate design enables a mechanic or experienced 4x4 enthusiast to disassemble, service or rebuild the ball joint at any time using basic hand tools.

The innovative design of these outstanding Blackhawk 4x4 Ultimate Adjustable Upper Control Arms includes a patented on-vehicle adjustment capability with a built-in caster increase of one degree. This allows for precise camber and caster corrections for wheel alignments and positioning.

Each Blackhawk 4X4 Ultimate Adjustable Upper Control Arm features a forged aluminium 6082 mainframe that delivers superior light weight strength that exceeds OEM specifications. They also feature maintenance free high quality rubber inner bushings and are finished with durable coatings that have been designed to withstand the harshest driving conditions. The threaded adjustment mechanism is nitride hardened, ensuring longer thread life and superior corrosion control.

Double mechanical 4140 chromoly locking nuts and state of the art manufacturing processes make the Blackhawk 4X4 Ultimate Adjustable Upper Control Arm range the optimum choice for serious 4X4 owners and off-road enthusiasts.

Importantly, all Blackhawk 4X4 Ultimate Adjustable Upper Control Arms are NCOP / ADR compliable for street legal use when fitted by an accredited installer with engineer sign-off / certification. This offers your customers total confidence in fitment and long-term use.

Providing your customers with peace of mind is important when selecting upgraded 4x4 suspension components. The Blackhawk 4X4 Ultimate Adjustable Upper Control Arm range has and continues to be subjected to rigorous product testing to ensure that this is the case.

Product testing has included Independent Finite Element Analysis (FEA) of UCA to NCOP VSB14. Physical tests of the adjustment mechanism have also been carried out to simulate fatigue, overturn and skid loading to validate its FEA Engineering endorsement. These premium quality suspension components have also undergone physical torsion testing, along with a stringent ongoing local quality assurance program, and are backed by a comprehensive warranty for additional peace of mind.

Various Blackhawk 4X4 Ultimate Adjustable Upper Control Arm applications are now available, with more applications to be added towards the end of 2023 and during 2024.

- BHU3881H - 2005+ to current Toyota Hilux ALL (excl 2022+ Rouge)

- BHU3841T - 200 series” Toyota Land Cruiser

- BHU3841P - Toyota Prado 120/150/FJ Cruiser

- BHU4981N - Nissan D40/D23 Navara

Blackhawk 4x4 is an industry leader in the design and manufacture of automotive steering and suspension components and is part of Bapcor, Australasia’s largest automotive aftermarket specialised company.

To find out more about Blackhawk 4x4 Ultimate Adjustable Upper Control Arms and to view the stockist listing, visit www.blackhawk4x4.com.au.